Nearly 400 Manufacturing Workers Were Killed on The Job in 2023: 10 Steps You Can Take to Address Workplace Dangers

Insights

1.08.25

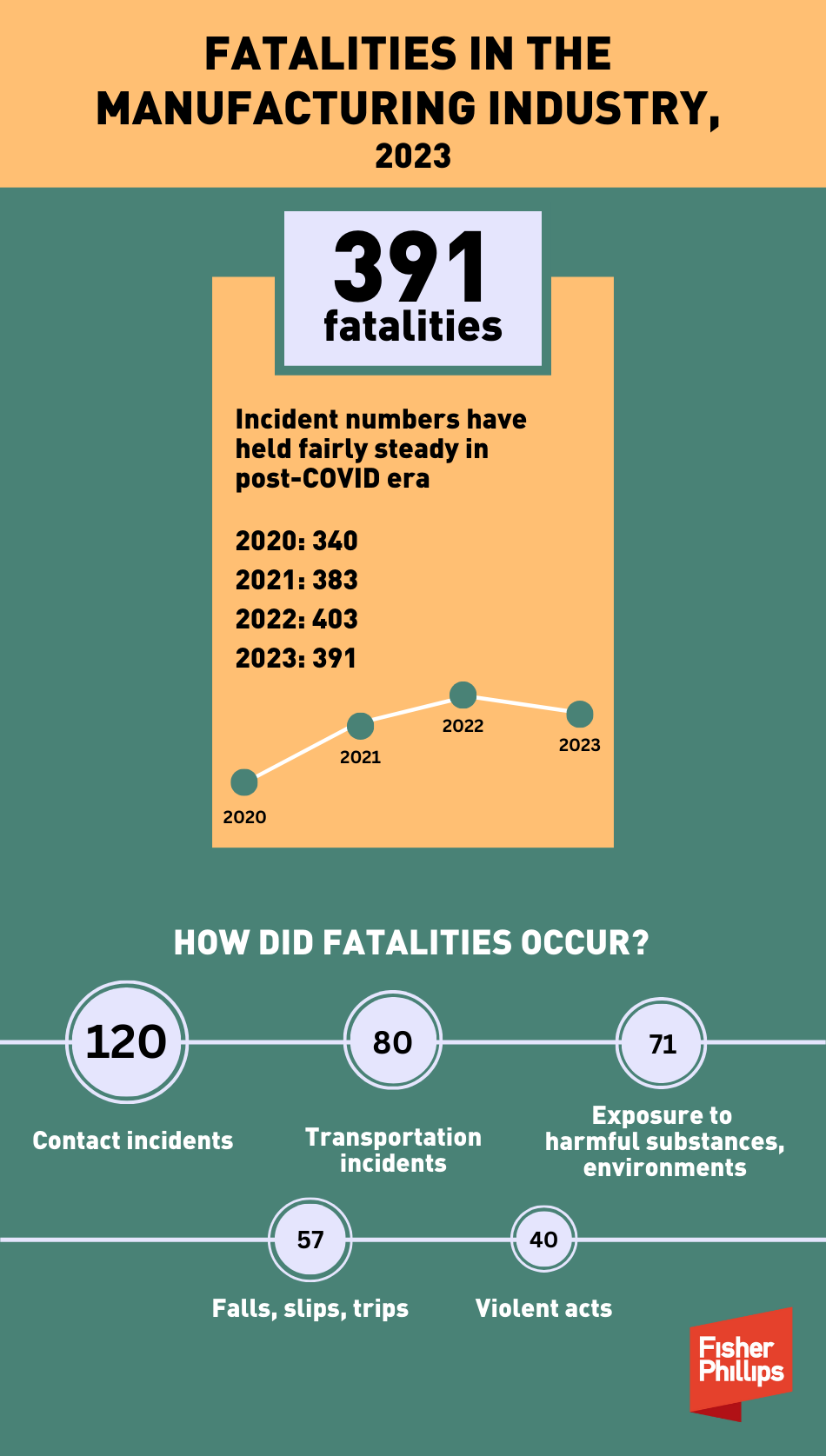

Recently released statistics revealed that nearly 400 workers in the manufacturing industry were killed on the job in the most recent reporting year, demonstrating once again that safety needs to be of paramount concern in the industry. According to the December 19 government release, the manufacturing fatality statistics have held fairly steady for the past several years. This Insight dives deeper into the numbers and provides manufacturing employers with 10 steps you can take to help reduce this number in the near year.

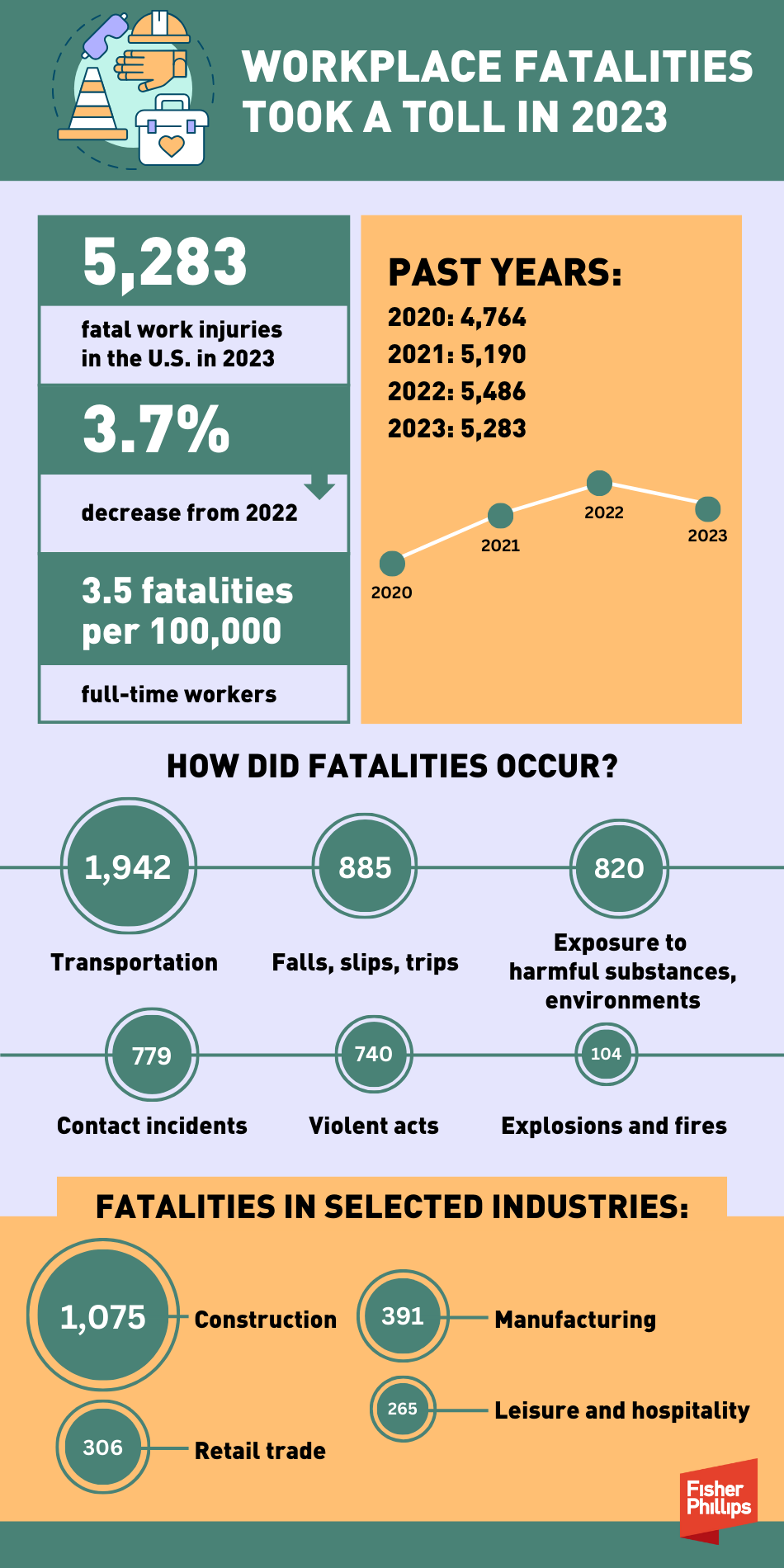

Workplace Fatalities Recap

Before we dive into industry-specific figures, here is an infographic providing some basic data across all fields for 2023. If you want to explore further, the raw data from the government can be found here.

Manufacturing Industry Detail

Diving deeper into the manufacturing industry, the following infographic tells the tale of an industry that should take safety seriously.

Note that more the 30% of all manufacturing deaths are the result of “contact incidents,” which can refer to a variety of situations – including a worker struck by an object, caught in or crushed by a machine or other equipment, or caught by a collapse of materials.

What Can Manufacturing Employers Do to Prevent Workplace Fatalities?

Here are a set of 10 recommendations to help manufacturing employers prevent fatalities at their worksites. OSHA also provides specific resources for various types of manufacturers that could be especially helpful depending on your business.

- Enforce Lockout/Tagout (LOTO) Procedures

Ensure equipment is de-energized and locked out before maintenance or repair. This eliminates the risk of unexpected machinery startups, a leading cause of manufacturing fatalities. - Provide Machine Guarding

Install guards on all moving parts, including belts, gears, and cutting blades. Proper guarding prevents contact with dangerous machinery, reducing amputations and fatalities. OSHA provides detailed resources on this topic. - Improve Forklift and Industrial Truck Safety

Forklift and powered industrial truck incidents are a major cause of manufacturing injuries and deaths. Train forklift operators, enforce speed limits, and designate clear pedestrian pathways. - Inspect Equipment Regularly

Conduct frequent inspections of machinery and tools for wear, defects, or malfunction. Properly maintained equipment reduces accidents caused by unexpected failures. - Mitigate Hazardous Chemical Risks

Hazard communication remains one of the most critical safety standards across all industries – but especially in the manufacturing field. Follow OSHA’s Hazard Communication Standard by labeling chemicals, providing safety data sheets, and training employees. Proper handling and storage prevent toxic exposures and explosions. - Control Ergonomic Hazards

Design workstations and tasks to minimize repetitive strain, overexertion, and awkward postures. Overexertion injuries can lead to long-term disability and life-threatening complications. - Prevent Slips, Trips, and Falls

Keep floors clean, dry, and free of obstacles. Use non-slip mats, proper lighting, and guardrails to eliminate one of the most common causes of workplace injuries. - Ensure Proper Ventilation

Good air quality protects workers from respiratory illnesses and chemical inhalation. Install and maintain ventilation systems to prevent exposure to harmful fumes, dust, and particulates. - Implement Comprehensive Safety Training

Train employees on hazard recognition, safe equipment use, and emergency protocols. Skilled workers are less likely to make fatal mistakes on the production floor. - Promote a Safety-First Culture

Engage all levels of the organization in prioritizing safety through leadership example, regular safety meetings, and employee feedback. A committed culture reduces complacency and risks.

Conclusion

We will monitor developments in this area and provide updates as warranted. Make sure you are subscribed to Fisher Phillips’ Insight System to get the most up-to-date information. If you have any questions, contact the author of this Insight, your Fisher Phillips attorney, or any member of our Workplace Safety or Manufacturing Industry groups.

Related People

-

- Colin P. Calvert

- Partner

-

- Todd B. Logsdon

- Partner

-

- Stephen C. Mitchell

- Regional Managing Partner