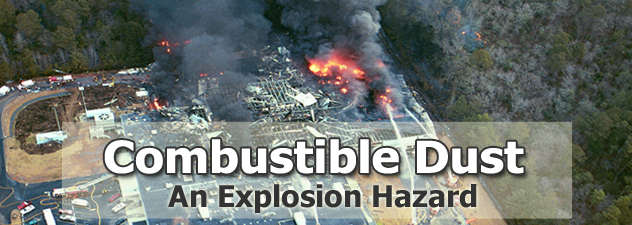

Combustible Dust, Housekeeping and Vacuums

Insights

11.12.13

One of my focus areas is combustible dust in the workplace. As I have written before, an extraordinary range of common products can cause an explosion and deflagration (pressure wave) under the right circumstances. One occasion is when a well meaning employer decides to clean that dust accumulation on overhead beams, ductwork and lights. This material is difficult to reach and has never presented a problem, so the employer decides to use pressurized air to blow off the dust. The dust cloud ignites and we have a combustible dust event. And any combustible dust event will be bad. A dust explosion or deflagration may occur when all of the following elements are present:

- Dust is combustible;

- Dispersed in air or another oxidant;

- Present in a concentration at or above the minimum explosible

concentration (MEC); - There is an ignition source; and

- Confinement.

With that background, I was intrigued by the Woburn Advocate news story below:

An explosion Tuesday that critically injured a worker in East Woburn was caused by an electrical charge that triggered a dust explosion, State Fire Marshal Stephen D. Coan, Woburn Interim Director of Fire and Emergency Services Robert DiPoli, and Woburn Police Chief Robert Ferullo, Jr. said in a joint statement released today.

An employee was using an improperly grounded vacuum to clean machinery when a build-up of static charge inside the vacuum ignited the dust, causing an explosion and subsequent small fire, officials said....

One man was critically injured and airlifted to a Boston hospital by MedFlight shortly after the first emergency call came in at 12:27 p.m. on Tuesday, Nov. 5. A worker from a neighboring company attempting to help the man suffered minor injuries, and a police officer was also treated as a precaution.

Powderpart uses metal powders and a 3-D printing process that involves lasers during production, according to the release.

I am not privy to inside information and do not know if indeed improper use of a vacuum to clean up metal powders triggered this event, but that sort of incident has occurred many times before. Consider the excerpt below from OHS Online magazine:

Industrial vacuum cleaners to control fugitive combustible dust should be suitable for use in Class II Div 2 areas. "Vacuum cleaners in particular are vulnerable to ignition, and that is why there are only a few companies that know how to do that properly," Stevenson said. "They take extraordinary care to make sure there is no chance for the product to come into contact with anything ignitable."

Any time there is powder flowing in one direction through a plastic vacuum-cleaning hose, it can create a significant static electric charge. In addition, there is the possibility there may be static electricity buildup on individual dust particles. If a charged, ungrounded hose used to vacuum combustible dust powder were to contact an object that was grounded, the static electricity could then arc and trigger a violent explosion. This is why OSHA has issued numerous citations for using standard vacuum cleaners where Class II Div 2 equipment is required.

….

"There are so many problems with vacuums; they themselves are hazards in an industrial environment," he said. First and foremost, they are not grounded or classified for Class II Div 2 areas. They shock workers, they clog easily, and workers don't want to use them. If workers don’t use them, fugitive dust is accumulating in the plant.

Employing an industrial vacuum cleaner that is redundantly grounded in five different ways "eliminates the possibility of any kind of explosion from the vacuum," said Bobbitt.

Moral of this story?

Evaluate your site and if necessary, conduct a full Process Hazard Analysis (PHA). Proper housekeeping is often the foundation of your program, and a key is to use the proper methods. Choose the correct vacuum. I won’t revisit the compliance areas for combustible dust, but I do encourage you to read the Sample questions CSHOs may use during the course of an inspection.

What types of combustible dust does the facility have?

Does the facility have a housekeeping program with regular cleaning frequencies established for floors and horizontal surfaces, such as ducts, pipes, hoods, ledges, and beams, to minimize dust accumulations within operating areas of the facility? Under the housekeeping program, is the dust on floors, structural members, and other surfaces removed concurrently with operations? Is there dust accumulation of 1/32 inch thick, or greater? For housekeeping violations, what are the dimensions of the room and the dimensions of the area covered with the dust?

Are the dust-containing systems (ducts and dust collectors) designed in a manner that fugitive dusts are not allowed to accumulate in the work area?

Are dust collectors greater than 8 cubic feet in volume located inside of buildings?

If dust explosion hazards exist in rooms, buildings, or other enclosures, do such areas have explosion relief venting distributed over the exterior walls of buildings and enclosures? Is such venting directed to a safe location away from employees?

Does the facility have isolation devices to prevent deflagration propagation between pieces of equipment connected by ductwork?

Does the facility have an ignition control program, such as grounding and bonding and other methods, for dissipating any electrostatic charge that could be generated while transporting the dust through the ductwork?

Does the facility have separator devices to remove foreign materials capable of igniting combustible dusts?

Are electrically- powered cleaning devices, such as sweepers or vacuum cleaners used in dusty areas, approved for the hazard classification, as required under 1910.307(b)?

Is smoking permitted only in safe designated areas?

Are areas where smoking is prohibited posted with "No Smoking" signs?

Is the exhaust from the dust collectors recycled?

Does the dust collector system have spark detection and explosion/deflagration suppression systems? (There are other alternative measures.)

Are all components of the dust collection system constructed of noncombustible materials?

Are ducts designed to maintain sufficient velocity to ensure the transport of both coarse and fine particles?

Are duct systems, dust collectors, and dust-producing machinery bonded and grounded to minimize accumulation of static electrical charge?

Is metal ductwork used?

In areas where a hazardous quantity of dust accumulates or is present in suspension in the air, does all electrical wiring and equipment comply with 1910.307(b) requirements?Does the facility allow hot work only in safe, designated areas?

Are bulk storage containers constructed of noncombustible materials?

Does the company use methods to dissipate static electricity, such as by bonding and grounding?Are employees who are involved in operating, maintaining, and supervising facilities that handle combustible dust trained in the hazards of the combustible dust?

Are MSDSs for the chemicals which could become combustible dust under normal operations available to employees?

Related People

-

- Howard A. Mavity

- Partner